https://truehealth.prohealthlink.com/

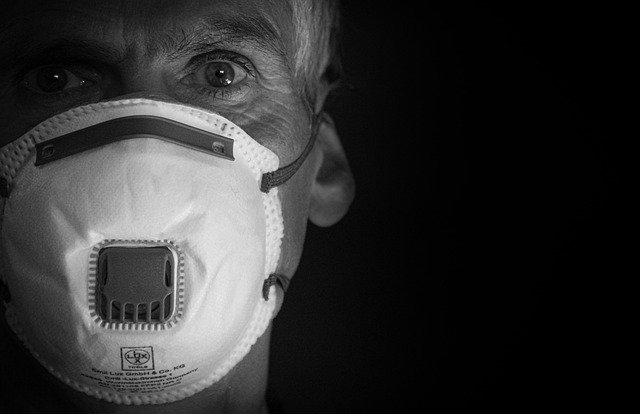

Occupational Health and Safety (OHS) is a critical component of maintaining a safe working environment across North America. As industries grow and evolve, the risks associated with them also increase, making it essential for employers to adopt rigorous safety protocols. Among the most crucial aspects of workplace safety is Respirator Fit Testing. Particularly vital in environments where workers are exposed to airborne contaminants, respirator fit testing ensures that respiratory protective equipment (RPE) functions effectively, safeguarding workers’ health.

Table of Contents

The Importance of Respirator Fit Testing

Respirator fit testing is not merely a regulatory requirement—it is a vital practice that ensures workers are adequately protected against respiratory hazards. Exposure to airborne contaminants such as dust, chemical vapors, gases, and biological agents can lead to severe health complications, including chronic respiratory diseases, lung cancer, and occupational asthma. These hazards are present in various industries, including construction, manufacturing, healthcare, and mining, making respirator fit testing essential across multiple sectors in North America.

In both the United States and Canada, the importance of respirator fit testing is emphasized by OHS regulations at federal, state, provincial, and territorial levels. In the U.S., the Occupational Safety and Health Administration (OSHA) sets forth standards that mandate respirator fit testing, while in Canada, similar guidelines are provided by the Canadian Centre for Occupational Health and Safety (CCOHS) and provincial regulatory bodies. Compliance with these regulations is essential for protecting workers’ health and ensuring that employers meet their legal obligations.

Key Components of an Effective Respirator Fit Testing Program

A comprehensive respirator fit testing program is a crucial element of any organization’s health and safety strategy. Below are the key components that such a program should include:

1. Conducting a Comprehensive Respiratory Hazard Assessment

The foundation of any respirator fit testing program is a thorough Respiratory Hazard Assessment. This involves identifying and evaluating the specific airborne hazards present in the workplace. Key factors to consider include:

- Type of Contaminants: Determine the nature of airborne hazards (e.g., dust, fumes, gases, vapors) and their sources.

- Concentration Levels: Measure the concentration of contaminants in the air using appropriate monitoring equipment.

- Duration of Exposure: Assess how long workers are exposed to these hazards during their shifts.

- Work Environment Conditions: Evaluate environmental factors such as temperature, humidity, and ventilation, which can affect the efficacy of respiratory protection.

This assessment is critical for identifying at-risk workers and determining the level of respiratory protection required, guiding the selection of appropriate respirators.

2. Selecting Suitable Respirators

Following the respiratory hazard assessment, the next step is the Selection of Suitable Respirators. The choice of respirator should be based on the specific contaminants workers are exposed to, the environment they work in, and the level of protection needed. Some common types of respirators include:

- N95 Respirators: Effective against particulate contaminants such as dust, mists, and fumes. Widely used in both the U.S. and Canada, especially in healthcare settings.

- Half-Mask and Full-Face Respirators: Offer protection against a broader range of contaminants, including certain chemical vapors and gases.

- Powered Air-Purifying Respirators (PAPRs): Provide higher levels of protection and are more comfortable for long-term use, particularly in environments with high contamination levels.

- Self-Contained Breathing Apparatus (SCBA): Typically used in environments with unknown or highly toxic concentrations of contaminants, such as in firefighting or confined spaces.

The selected respirators must comply with relevant standards, such as the NIOSH (National Institute for Occupational Safety and Health) certification in the United States or the equivalent CSA (Canadian Standards Association) certification in Canada.

3. Implementing Fit Testing Procedures

The core of any respirator fit testing program is the Fit Testing Procedure. This process ensures that the selected respirator fits the worker’s face correctly, providing an effective seal that prevents contaminants from bypassing the respirator. There are two primary types of fit testing:

- Qualitative Fit Testing (QLFT): A pass/fail test that relies on the wearer’s sensory detection of a test agent (such as saccharin, Bitrex, or isoamyl acetate). The test checks if the wearer can detect the test agent’s taste, smell, or irritation, which would indicate a poor fit.

- Quantitative Fit Testing (QNFT): A more precise method, QNFT uses a machine to measure the actual amount of leakage into the respirator. This test provides a numerical result called a “fit factor,” which quantifies how well the respirator fits.

Fit testing should be conducted:

- Initially: Before a worker uses a respirator for the first time.

- Annually: To ensure continued effectiveness, even if there are no significant changes in the worker’s facial structure.

- After Facial Changes: If there are significant changes in the worker’s facial structure due to weight gain/loss, dental work, or other factors that might affect the fit.

In both the U.S. and Canada, these fit testing procedures are mandated by OSHA and CCOHS, respectively, with specific guidelines that employers must follow to ensure compliance.

4. Comprehensive Training and Education

An often-overlooked aspect of respiratory protection programs is Training and Education. Even with the right respirator, improper usage can significantly reduce its effectiveness. Therefore, it’s crucial that workers are adequately trained in the following areas:

- Proper Donning and Doffing Techniques: Workers should know how to correctly put on (don) and remove (doff) the respirator to ensure a proper seal and prevent contamination.

- User Seal Checks: Every time a respirator is worn, a user seal check should be performed to confirm that the respirator is seated correctly and there are no leaks.

- Maintenance and Care: Training should cover how to clean, inspect, and store respirators properly to maintain their functionality.

- Limitations of Respirators: Workers should be aware of the respirator’s limitations, including the specific contaminants it protects against and situations where it may not provide adequate protection.

In North America, OSHA requires employers to provide comprehensive training as part of their Respiratory Protection Program, while in Canada, similar requirements are outlined by CCOHS and provincial regulations. Training should be ongoing, with refreshers provided regularly or when new respirators are introduced.

5. Rigorous Record Keeping and Documentation

Record Keeping and Documentation are critical for demonstrating compliance with OHS regulations and for tracking the effectiveness of the respirator fit testing program. Records should include:

- Fit Test Results: Document the date, type of fit test conducted, the respirator model and size, and the results.

- Training Records: Keep records of training sessions, including the topics covered, the date, and the names of attendees.

- Maintenance Logs: Document the regular maintenance and inspection of respirators.

- Program Evaluations: Record any program evaluations or audits conducted, including recommendations for improvements.

These records should be maintained for at least the duration required by OSHA in the U.S. or provincial/federal regulations in Canada and should be readily accessible for review by OHS inspectors or for internal audits.

6. Ongoing Program Evaluation and Continuous Improvement

A successful respirator fit testing program is not static; it should evolve based on new information, changing work conditions, and technological advancements. Ongoing Program Evaluation is crucial to ensure the program remains effective and compliant with the latest OHS standards. Key activities include:

- Regular Audits: Conduct regular internal audits to evaluate the effectiveness of the fit testing program. Look for any gaps or issues that need to be addressed.

- Feedback from Workers: Encourage workers to provide feedback on the comfort and functionality of their respirators, as well as the fit testing process itself.

- Staying Updated with Regulations: OHS regulations can change, and new safety guidelines may be introduced. Staying informed about these changes ensures that your program remains compliant.

- Incorporating Technological Advancements: New technologies, such as more advanced fit testing equipment or improved respirator designs, can enhance the effectiveness of your program. Consider incorporating these advancements as they become available.

Compliance with North American OHS Standards

In North America, respirator fit testing programs must comply with both U.S. and Canadian OHS standards. The U.S. Occupational Safety and Health Administration (OSHA) and the Canadian Centre for Occupational Health and Safety (CCOHS) provide guidelines and resources to help employers understand and comply with these requirements. Additionally, state and provincial regulatory bodies, such as Cal/OSHA in California and WorkSafeBC in British Columbia, may have specific regulations that apply.

Compliance with these standards is not just about avoiding fines or penalties; it’s about protecting the health and safety of workers. Employers have a legal and moral obligation to ensure that their workers are not exposed to unnecessary risks, and a robust respirator fit testing program is a key component of fulfilling this obligation.

Conclusion: A Commitment to Workplace Safety

Respirator fit testing is a cornerstone of workplace safety across North America. By implementing a comprehensive and well-maintained respirator fit testing program, employers can significantly reduce the risk of respiratory hazards, ensuring that their workers are protected and their operations are compliant with both U.S. and Canadian OHS regulations.

Remember, workplace safety is an ongoing commitment that requires vigilance, regular updates, and a proactive approach. As industries evolve and new challenges arise, so too must your safety programs adapt to continue providing effective protection. A successful respirator fit testing program is not just a regulatory checkbox—it’s an investment in the health, well-being, and productivity of your workforce.

By prioritizing respirator fit testing and other safety measures, you are not only complying with the law but also fostering a culture of safety that benefits everyone involved. Make respirator fit testing a regular part of your OHS strategy, and ensure that your workers are equipped with the best possible protection against respiratory hazards.